Introduction: Maintaining a well-functioning sewer system is crucial for the smooth operation of any property, be it residential, commercial, or industrial. When faced with damaged or deteriorating sewer pipes, traditional repair methods often involve significant excavation and disruption. However, a modern and cost-effective alternative known as Cured-In-Place Pipe (CIPP) reparation has gained popularity. In this blog, we'll delve into the details of CIPP, providing a step-by-step guide for carrying out this innovative sewer pipe repair method.

What is Cured-In-Place Pipe (CIPP)?

Cured-In-Place Pipe, commonly referred to as CIPP, is a trenchless method used for rehabilitating damaged sewer pipes without the need for extensive excavation. The process involves creating a new, durable pipe within the existing one, effectively eliminating the need for disruptive digging. This method is not only efficient but also reduces costs and minimizes environmental impact.

Step-by-Step Guide to CIPP Sewer Pipe Reparation:

1. Initial Inspection:

Begin the process by thoroughly inspecting the damaged sewer pipe using advanced technologies such as CCTV cameras. Identify the extent of the damage, including cracks, leaks, and structural issues. This inspection is crucial for determining whether CIPP is a suitable solution for the specific case. Take advantage of our compact, lighter, and portable inspection camera—check it out here !

2. Pipe Cleaning:

Before applying the CIPP liner, it's essential to clean the existing pipe thoroughly. High-pressure water jetting or mechanical cleaning methods can be employed to remove debris, sediment, and other obstructions, ensuring a smooth surface for the liner to adhere to. Take advantage of our cleaning tools - Sandpaper holders and Cutters) !

3. Measurement and Liner Preparation:

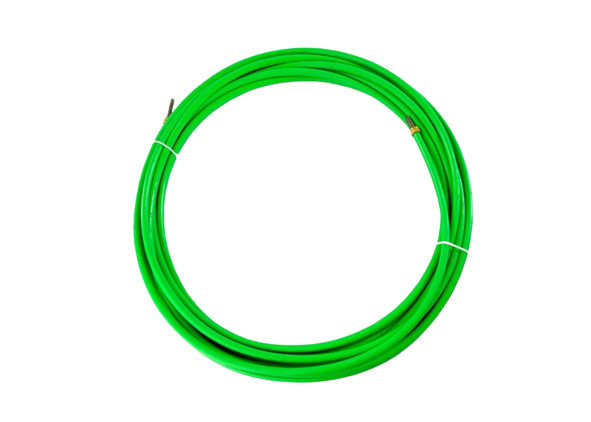

Accurately measure the length and diameter of the damaged pipe. With these measurements, prepare the CIPP liner, which is typically a flexible fabric tube saturated with a resin. The resin hardens when exposed to heat or UV light.

4. Installation:

Insert the CIPP liner into the damaged pipe using various methods such as inversion or pulling. The liner is positioned using a calibrated guide to ensure proper alignment. Once in place, the liner is inflated, pressing against the inner surface of the damaged pipe.

5. Curing Process:

Activate the curing process by applying pressure inside the packer with any compressor type. This causes the resin to harden, creating a seamless, jointless, and structurally sound pipe within the existing one. The curing time depends on the specific resin used and the curing method.

6. Quality Control:

After the curing process is complete, conduct a final inspection using an inspection camera to ensure the integrity of the newly formed pipe. Verify that there are no defects, and the liner adheres properly to the existing pipe walls.

7. Reconnection and Testing:

Once satisfied with the CIPP installation, reconnect the sewer system components and conduct thorough testing to ensure the repaired pipe meets industry standards. This may involve pressure testing and flow analysis.

Benefits of Cured-In-Place Pipe Reparation:

1. Cost-Effective:

CIPP eliminates the need for extensive excavation, reducing labor and material costs associated with traditional repair methods.

2. Minimized Disruption:

Property owners experience minimal disruption as CIPP is a trenchless technology, preserving landscapes and minimizing inconvenience.

3. Durability and Longevity:

CIPP creates a strong and durable pipe within the existing one, extending the lifespan of the sewer system.

4. Environmental Impact:

CIPP is an environmentally friendly solution that reduces the carbon footprint associated with traditional excavation methods.

Conclusion:

Cured-In-Place Pipe reparation has revolutionized sewer pipe rehabilitation, offering an efficient, cost-effective, and environmentally friendly alternative to traditional excavation methods. By following the step-by-step guide outlined in this blog, property owners and professionals alike can confidently address sewer pipe issues while minimizing disruption and maximizing long-term durability. Embrace the future of sewer repair with CIPP technology.