Trenchless Pipe lining

Say goodbye to disruptive and costly excavation. Our trenchless pipe lining solutions offer a seamless and efficient process for repairing your pipelines.

Trenchless Pipe Lining

Trenchless Technology: Our Drain Pipe Rehab System

The DRS Drain Pipe Rehab System is an easy to use CIPP pipe repair system, designed for the local repair of underground damaged sewage pipes. The system is a quick and cost efficient alternative to the traditional method of excavation.

This lateral and spot repair system is designed for pipes with 4" to 6" diameters and can also be used to repair the 4" to 6" transition joint.

Click here to see the advantages of the DRS Lateral & Spot Repair System

Exterior Access Point

Trenchless Pipe Lining Installation video courtesy of Drain Dancar

Interior Access Point

Trenchless Pipe Lining Installation video courtesy of Drain Dancar

What is CIPP lining or Trenchless Pipe Lining?

CIPP lining which is known as “cured-in-place pipe lining” is commonly referred to as Trenchless pipe lining, Sewer pipe lining, CIPP Trenchless pipe repair and CIPP Trenchless sewer repair, among other names.

Trenchless pipe lining is a cost-effective method of repairing damaged sewer laterals without the need for trench excavation. Using the main cleanout as a direct access, we insert a patch liner made of resin-impregnated fiberglass and create a durable pipe within a pipe. This technology repairs sewers that are infiltrated by roots, partially missing, and on the verge of complete collapse. Pipe relining is the most cost efficient solution to any sewer drain problem!

Once a homeowner reaches out to a DRS installer, a certified professional is dispatched to the home to assess the condition of the drain. After passing a camera in the drain, the drain professional determines whether or not trenchless pipe lining is a viable option.

The Rehabilitation Procedure

The certified installer begins by protecting and covering the work area with protective carpets and tarps, ensuring a clean and professional work environment.

The host pipe is then 100% cleaned and cleared from any roots or debris.

We are now ready to prepare for a pipe liner installation!

The fiberglass sheet is carefully laid out on the working table and now it is ready for the 'wet-out' phase with the CIPP resin.

The resin is then mixed between three to five minutes by combining the two components (A into B) and evenly spread into the fiberglass cloth, wetting it out completely.

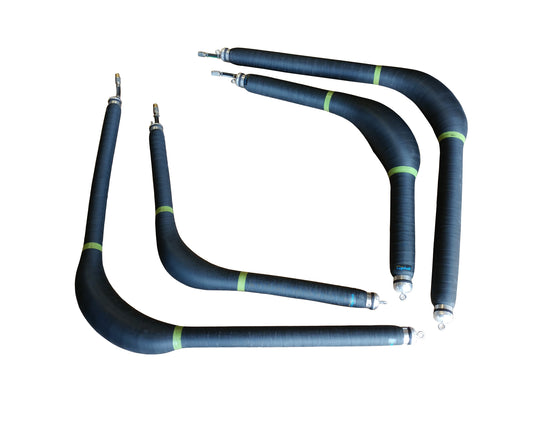

Once the fiberglass cloth is impregnated with the resin, it is then rolled tightly around a tubular CIPP packer and inserted into the main clean-out. The CIPP packer is pushed through the sewer line and placed at the affected area of the pipe.

The CIPP packer is then inflated with compressed air, pushing the impregnated fiberglass against the inside walls of the host pipe. Over the course of 90 minutes, the resin polymerizes, hardens, and adheres to the host pipe. This results in a tightly sealed high-quality trenchless pipelining rehabilitation.

Once the resin has hardened, the CIPP packer is then deflated and removed from the host pipe. The homeowner's plumbing is now 100% functional!

Another successful Drain Rehab Solutions job!

CIPP Equipments

-

Air Push Rod for Packer

Regular price From $103.99 CADRegular priceUnit price / per -

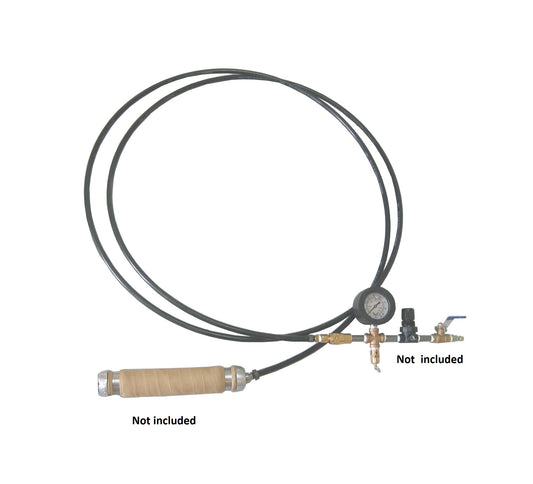

CIPP Air Regulator Kit

Regular price $279.99 CADRegular priceUnit price / per -

CIPP Inflatable Curved Packer

Regular price From $1,395.99 CADRegular priceUnit price / per -

CIPP inflatable Long Packer

Regular price From $985.99 CADRegular priceUnit price / per